During its April 12 committee of the whole meeting, the United Counties of Prescott and Russell council (UCPR) received a report from John Candie, executive director of the Prescott-Russell Community Development Corporation (PRCDC), and John Liptak, president and CEO of Nubuild CEO, about the NuBuild Project, and a request for the UCPR to support efforts to have the federal and provincial governments become strategic partners in the project. Nubuild operates out of a single construction yard in Vaughan but wants to expand into Eastern Ontario.

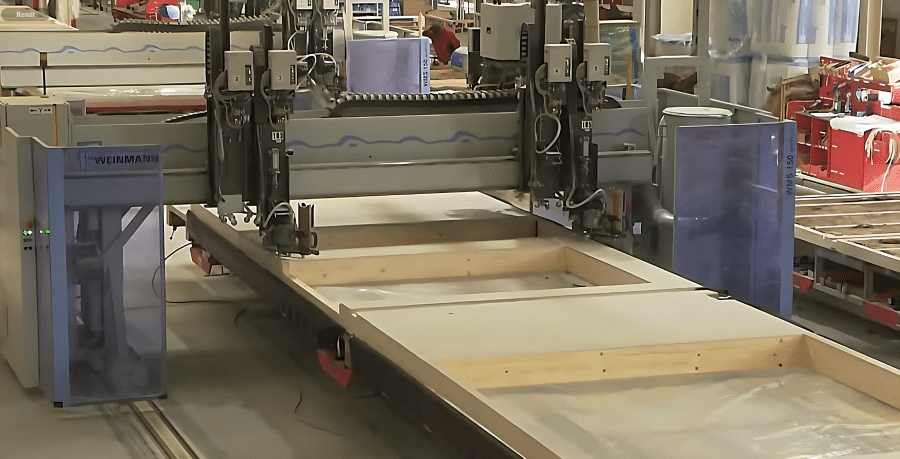

The NuBuild project is described as “the most advanced, technology-enabled manufacturing of housing construction in the world”, according to the presentation. It uses robotic AI construction techniques to build residential and commercial buildings with less time, less costs, less wastes, and less emissions, without sacrificing quality. Once up and running, factories can construct residential and commercial buildings 68 percent faster than on-site construction with up to 20 percent in cost savings.

The project also concerns itself with several social and economic priorities, such as environmental concerns, Indigenous support, and affordable housing. Nubuild’s 660,000-square-foot Super Factory claims 92 percent less carbon emissions and 96 percent less material waste than traditional stick frame building techniques. The project has an agreement with the National Aboriginal Capital Corporations Association (NACCA) and purchases wood from Indigenous sawmills, expanding transportation hubs with Indigenous businesses.

Liptak also said that Nubuild furthers more general priorities, such as jobs, international trade, and technological advancement. The presentation stated that each factory provides 650 high-quality, high-paying jobs, as well as 5,280 support positions, that take place in a safe, warm, clean, and modern work environment spanning multiple industries. Liptak said that Nubuild introduces advanced AI automation and robotics technology to local manufacturing, and that a Russell Township factory would be able to export finished housing products to the United States.

Liptak said the project already has support from François-Philippe Champagne, the Minister of Innovation, Science, and Industry, as well as Marie-France Lalonde, Parliamentary Secretary to the Minister of Immigration, Refugees and Citizenship, and Ontario Premier Doug Ford. He said that the federal government expressed interest in building more Nubuild plants across Canada, but to start with, Nubuild wants to build its first branch plant in the Vars Industrial Park.

Nubuild replicates the formula used in Germany and Sweden for similar operations, only “with a little bit more advancement” to turn it into “a Canadian-type environment”. It employs two executive advisors, Ola Magnusson and Helena Lidelöw, who have built two factories in Europe and maintained them at 96 percent efficiency. Liptak said that Magnusson and Lidelöw will run the factory for the first year to bring it up to the same level. They’re also planning several subsidiary factories to produce supplementary materials, such as interior finishes.

Nubuild is planning for $300 million in mezzanine funding, which is a type of loan with the possibility of being turned into stock in the company. The company already has $150 million in foreign investments, and is expecting another $150 million from federal and provincial sources in Canada. Liptak finished the presentation by reiterating that Nubuild isn’t asking for money from the UCPR. The company is asking the UCPR to help support Nubuild’s partnership proposal to the federal and provincial governments.

Mayor Genevieve Lajoie of Casselman was concerned that such a large factory would drive smaller contractors out of business, but Liptak said that Nubuild isn’t in the same market. It focuses mainly on multi-unit residences and large contracts, whereas smaller contractors mainly focus on renovations and build perhaps ten homes per year. In addition, he said that there is no shortage of customers in the region, there is a shortage of materials causing a backlog.

The matter will be decided at the next general meeting.